Custom Printed Pins

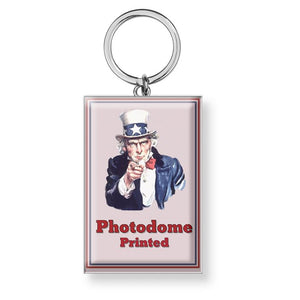

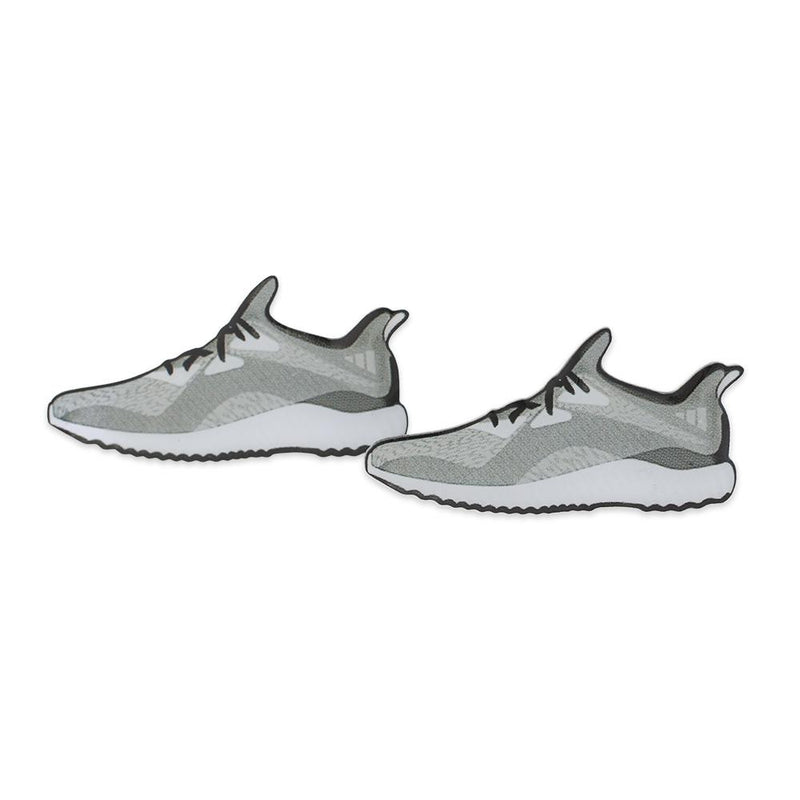

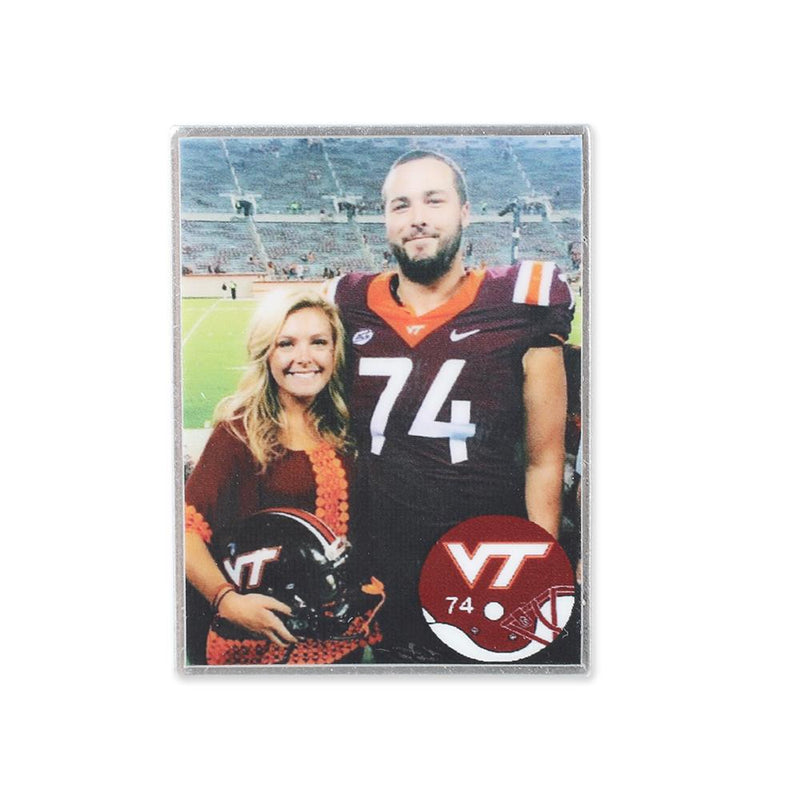

Photodome Printed

Photorealistic custom pins perfect for detailed designs or gradients

Any design with any shape

Replicate Photos

Full CMYK Print

Epoxy Dome

No Enamel

Rush Printed Pins 🇺🇸

Fastest turnaround pin, printed design

USA printed on stock shapes

Fastest Turnaround

Made In USA

Full Color Print

Silver Or Gold Plating

Dimensionally Printed 🇺🇸

Printed details on top of an enamel filled cavity

USA Enamel + Print

Enamel Base

Raised Print

Quick Turn

USA Made

Hard Enamel + Print Pins

Print the extra details on your custom pin

Best for extra details

Smooth Finish

Printed Color On Enamel

Exact

Fine Details

Wood Pins With Color

Printed color details on top of a wood base

Colored Logo On Wood Pins

Wood + Metal Base

Raised Print

Quick Turn

USA Made

Not sure which style?

Order A Sample Kit - $4.99You may also like these pins

Soft Enamel Pins

Our most popular pin

Hard Enamel Pins

Premium custom enamel pin with smooth finish